Tools of communication have transformed American society time and again over the past two centuries. The Museum has preserved many instruments of these changes, from printing presses to personal digital assistants.

The collections include hundreds of artifacts from the printing trade and related fields, including papermaking equipment, wood and metal type collections, bookbinding tools, and typesetting machines. Benjamin Franklin is said to have used one of the printing presses in the collection in 1726.

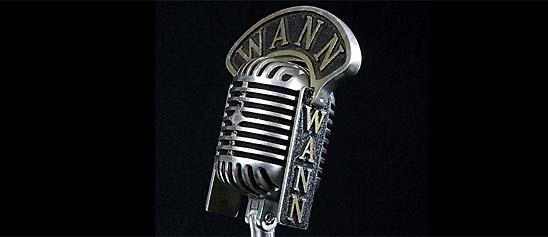

More than 7,000 objects chart the evolution of electronic communications, including the original telegraph of Samuel Morse and Alexander Graham Bell's early telephones. Radios, televisions, tape recorders, and the tools of the computer age are part of the collections, along with wireless phones and a satellite tracking system.

Our collection database is a work in progress. We may update this record based on further research and review. Learn more about our approach to sharing our collection online.

If you would like to know how you can use content on this page, see the Smithsonian's Terms of Use. If you need to request an image for publication or other use, please visit Rights and Reproductions.