This model was filed with the application to the U.S. Patent Office for Patent Number 95,281 issued to B. F. Sturtevant of Jamaica Plain, MA on September 28, 1869. Mr. Sturtevant’s patent involved recirculating the air being heated in a room or apartment.

- Description

-

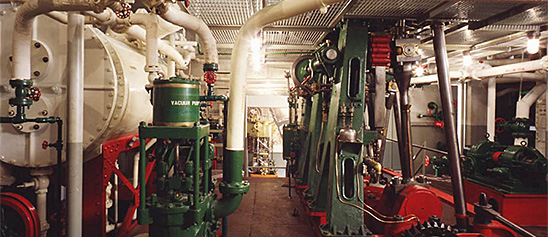

This model was filed with the application to the U.S. Patent Office for Patent Number 95,281 issued to B. F. Sturtevant of Jamaica Plain, MA on September 28, 1869. Mr. Sturtevant’s patent involved recirculating the air being heated in a room or apartment. He had developed improved designs for rotary blowers in the past, initially to provide ventilating air in the work areas of his factory which made wooden pegs for shoes. In this patent he combined the rotary blower, which would be driven by a steam engine, with a heat exchanger through which passed the exhaust steam of the engine. The exhaust steam travelled through the vertical openings shown in the center of the image of the patent model. The air to be heated passed through several horizontal pipes inside the heat exchanger cylinder. The steam heated these pipes which in turn transferred heat to the air. The blower is at the left of the model. Its inlet air came via the return duct at the right after passing through the heat exchanger. Heated air was forced by the blower into the room at the lower left. The inventor claimed his design improved the efficiency of a furnace by continuously reheating the same air. Only a portion of the heat was lost in the room being heated, and a significant energy savings was claimed over heating cold outside air.

-

Sturtevant was extremely successful with this and his many other patents relating to heating and ventilation. In 1860 he founded the B. F. Sturtevant Co. which was successful and long lived; Westinghouse bought the company in 1945, and operations continued at the Hyde Park, MA factory until its closing in 1989. The company’s equipment was installed in many private and public buildings including the U.S. Capitol and the “New National Museum, Washington, D.C” – now the Smithsonian National Museum of Natural History.

-

The patent model is constructed of wood and metal. It represents the central duct work, heat exchanger, and rotary blower of Sturtevant’s patent. The air pipes are modelled inside the heat exchanger.

- Location

-

Currently not on view

- date made

-

ca 1869

- patent date

-

1869-09-28

- inventor

-

Sturtevant, B. F.

- ID Number

-

ER.308677

- catalog number

-

308677

- accession number

-

89797

- patent number

-

95,281