Thomas and Bushnell manufactured this steam engine indicator, serial number 482, based on a design by Joseph Bachelder, who received patent number 360644 on April 5, 1887. It consists of a brass piston, a brass cylinder, and a large drum with a coil spring and a single record.

- Description

-

Thomas and Bushnell manufactured this steam engine indicator, serial number 482, based on a design by Joseph Bachelder, who received patent number 360644 on April 5, 1887. It consists of a brass piston, a brass cylinder, and a large drum with a coil spring and a single record. The cantilever spring is enclosed in the tube; an adjustable fulcrum renders one spring usable over a range of values. Two springs are included: one low pressure 10-25 (20-50 pounds) and one high pressure 30-90 (60-175 pounds).

-

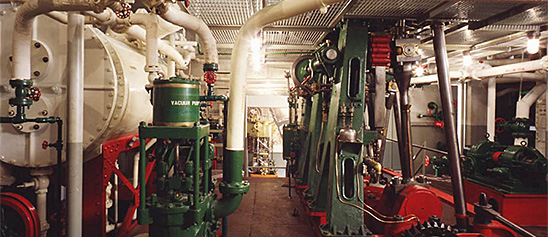

An engine indicator is an instrument for graphically recording the pressure versus piston displacement through an engine stroke cycle. Engineers use the resulting diagram to check the design and performance of the engine.

-

A mechanical indicator consists of a piston, spring, stylus, and recording system. The gas pressure of the cylinder deflects the piston and pushes against the spring, creating a linear relationship between the gas pressure and the deflection of the piston against the spring. The deflection is recorded by the stylus on a rotating drum that is connected to the piston. Most indicators incorporate a mechanical linkage to amplify the movement of the piston to increase the scale of the record.

-

When the ratio of the frequency of the pressure variation to the natural frequency of the system is small, then the dynamic deflection is equal to the static deflection. To design a system with a high natural frequency, the mass of the piston, spring, stylus, and mechanical linkage must be small, but the stiffness of the spring must be high. The indicator is subjected to high temperatures and pressures and rapid oscillations, imposing a limitation on the reduction in mass. Too stiff a spring will result in a small displacement of the indicator piston and a record too small to measure with accuracy. Multiplication of the displacement will introduce mechanical ad dynamic errors.

-

The parameters of the problem for designing an accurate and trouble free recorder are such that there is no easy or simple solution. Studying the variety of indicators in the collection shows how different inventors made different compromises in their designs.

- Location

-

Currently not on view

- date made

-

1887

- ID Number

-

MC.316789

- catalog number

-

316789

- accession number

-

228496