Sewing Machine Patent ModelPatent No. 3,389, issued December 27, 1843George Henry Corliss of Greenwich, New YorkIn 1825, George Corliss’s physician father moved the family to Greenwich, New York, where George, then 8, grew up.

- Description

-

Sewing Machine Patent Model

-

Patent No. 3,389, issued December 27, 1843

-

George Henry Corliss of Greenwich, New York

-

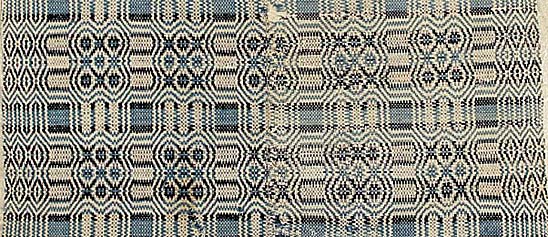

In 1825, George Corliss’s physician father moved the family to Greenwich, New York, where George, then 8, grew up. The son spent several years as a young man clerking in a country store and in 1838 opened his own country store in Greenwich. While running the store, George received complaints about the stitching of leather boots from a customer. Since all stitching was done by hand, George wondered why a machine had not been invented that would stitch stronger seams.

-

He analyzed the saddler’s stitch, which was commonly used to stitch boot seams, and developed the concepts of the mechanisms that would be necessary to reproduce the stitch with a machine. By 1843, he had developed such a machine and received Patent Number 3,389. In his patent specification, he described the operation of the “Sewing Engine” as follows: “Like the common process of sewing by hand, it is provided in this machine that the article under operation be perforated for each stitch, and that the perforation be filled with a thread passed through it from each side. The instruments by which this is affected repeat their operations always at the same point. The article to be sewed is therefore moved at each stitch.” Knight’s Mechanical Dictionary of 1881 indicated that the machine was similar in operation to the Greenough patented in 1842 in the use of the running stitch. In his patent claims, Corliss noted the rectilinear and lateral movements of the awls; the movements of the needles; the combination of levers; the method of forming stitches; and the mechanism that prevents the entanglement of threads.

-

Hoping to promote his sewing machine patent, George moved his family to Providence, Rhode Island, in 1844 to gain financial backing and machine shop experience. Associating himself in business with John Barstow and Edwin J. Nightingale to develop and manufacture steam engines, Corliss received many patents relating to steam engines and their associated components. His interest in sewing machines was overtaken by his pursuit of improvements to steam engines, for which he became famous.

- Location

-

Currently not on view

- model constructed

-

before 1843-12-27

- patent date

-

1843-12-27

- inventor

-

Corliss, George H.

- ID Number

-

TE.T06110

- catalog number

-

T06110.000

- patent number

-

003389

- accession number

-

89797